FAQs

What is Backflow?

Backflow is the unwanted reverse flow of water from a contaminated source into the clean water supply. This can happen through either backpressure or backsiphonage, posing a health risk to drinking water systems.What Causes Backflow?

Backpressure occurs when the downstream pressure exceeds the supply pressure, often caused by equipment like pumps, boilers, or elevated storage tanks.

Backsiphonage happens when there’s a negative pressure (like a vacuum) in the supply line, often due to water main breaks or heavy firefighting activity, drawing contaminants back into the water system.

What is a Cross-Connection?

A cross-connection is any physical connection between the potable water system and a source of contamination, such as lawn sprinkler systems, private wells, or industrial equipment. Cross-connections increase the risk of backflow contamination.Do I Need a Backflow Prevention Assembly for Lawn Irrigation Systems?

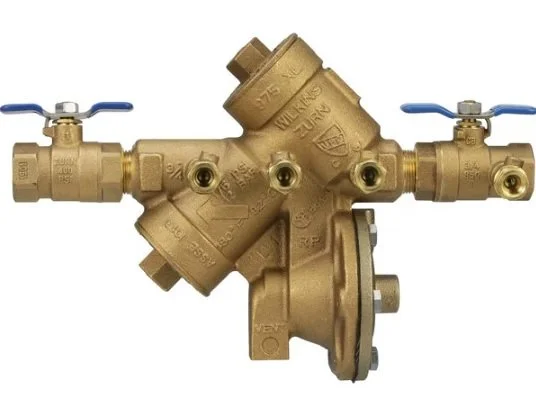

Yes, Texas regulations require irrigation systems to include a backflow prevention assembly to prevent stagnant water from being drawn into the public water supply.How Often Should a Backflow Prevention Assembly Be Tested?

According to state requirements, backflow prevention assemblies must be tested by a licensed professional upon installation and annually thereafter to ensure proper functionality.Why is Annual Testing Necessary?

Mechanical assemblies contain seals and moving parts that can degrade over time, leading to potential failures. Regular testing ensures these assemblies continue to protect the water system effectivelyHow Can I Schedule a Backflow Test?

You can contact a licensed backflow tester in your area to schedule a test. Some local water systems maintain a list of approved testers and may notify customers when annual testing is due.